Business Info

チタニウム

MTIG launches the world's lowest-priced dental implants

Nowadays dental implants are being switched from two-body to one-body.

There are several reasons behind the transition, including problems stemming from the existing two-body dental implants. In addition, the dental implant surgery is being increasingly standardized as a result of the development of dental techniques and advanced equipment.

While Zirconium dental implants are being manufactured and commercialized in Germany using the same process as that of MTIG, some domestic dental implant companies still rely on machining to manufacture titanium one-body implants.

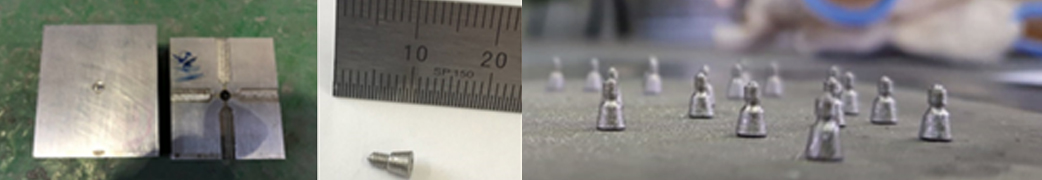

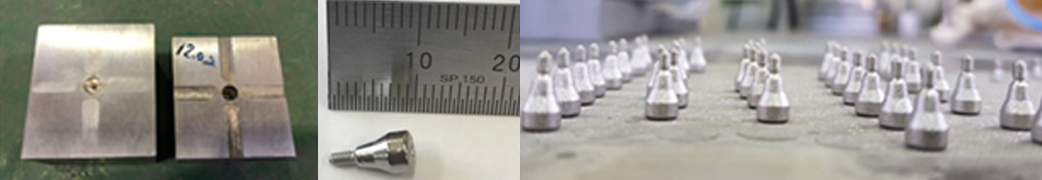

MTIG is the only company in the world equipped with advanced technology and facilities to mass-produce titanium implants through its titanium powder injection molding technology (which enhances productivity by over 1,000 times) and to automate the production process.

In the United States, for instance, if a foreign CNC machine processes dental implant bars imported at high prices, it can produce only about 60 implants in 10 hours.

On the other hand, MTIG produces dental implants priced at less than one-tenth of the current market price, and is capable of manufacturing some 120,000 implants in 10 hours with the same equipment cost.

- Two-body dental

implants currently in use -

There are two types of dental implants: the existing two-body implants and one-body implants.

The two-body dental implants currently used were first developed in the 1950s, when dental technology such as tooth and gum scanners and automated tools was immature.

Since it is tricky in nature to place the two-body dental implants in gums, the procedure used to be inevitably dependent on individual dentists’ skills. If implants were placed in a distorted direction, dentists had no choice but to use an angle adjusting abutment to cover the upper part of the implants with dentures as it was difficult to erect the implants straight.

- Problems of existing two-body dental implants

-

With the advancement of the state-of-the-art dental technology and equipment, people no longer need to rely on the two-body dental implant operation, which has a number of limitations.

In addition, the existing machined two-body dental implants have reached the limit of their use due to many side effects (screw loosening, breakage, inflammation, etc.). Also, machined titanium one-body dental implants have been already adopted by a growing number of dentists.

- Manufacturing process of titanium dental implants

- Currently, domestic and overseas titanium dental implants are being manufactured by machining with Swiss or Japanese CNC machines. FDA-certified titanium bars are used, which are imported from the United States or Japan with the price tag of about four times the cost of industrial titanium.

Manufacturing and sales of titanium

one-body dental implants in Korea

The material for dental implants is titanium, which causes no side effect even if it is implanted into a human body.

Titanium is particularly the best material for dental implants because it weighs the same as the teeth. One-body dental implants also have the same structure as that of the human teeth. Therefore, an increasing number of implant companies are manufacturing one-body dental implants by CNC machining, and dentists are choosing titanium one-body dental implants.

Comparison of ‘MTIG One-Body Dental Implant’ and ‘Machined Two-Body Dental Implant’

- Cover screw

- Healing abutment

MTIG has already been supplying titanium dental implant parts to a number of leading dental implant companies in Korea. The following picture shows the MTIG’s automated mass production process of dental implant parts.