Business Info

チタニウム

What kind of metal is the “new material of dream, titanium?”

Titanium's the element symbol is Ti. It is about twice as lighter than iron and about twice as strong as iron. It has strong corrosion resistance that does not corrode even in seawater for 100 years. It has high heat resistance, so it is used in several fields including space, aviation, defense, etc., and is also used in core parts such as nuclear power.

Especially, it is the only metal that can be inserted into the human body (orthopedic, dental implant, etc.) among the metals present on the earth.

It is the best metal among the metals found on the earth now and is called "new material of dream".

The reason why titanium cannot be popularized

The price of titanium is about 100 times higher than that of iron and about 10 times higher than that of stainless steel. Titanium is HCP structure (structure like a soccer ball), so it is very difficult to process large quantities of general metals such as forging, casting and bending (press).

Because parts cannot be produced in large quantities, parts are manufactured mainly by machining, so the cost of parts is very high

Why is new technology of MTIG so excellent?

- 01Mass production method

- MTIG is currently applying plastic injection method which is relatively low-cost manufacturing process. And the company enhances the productivity about 100 times thanks to mass production, automation production, 365 days production and minimization of production manpower.

- 02Localization of production equipment

- We have succeeded in fully localizing all the production equipment of the whole cycle from the raw materials to the final part production except the injection machine.

- 03MTIG has the only technology and production plant.

- MTIG is the only company that has a production facility.

Price competitiveness and excellent profitability

- Price is low and labor costs are reduced thanks to 24/365 continuous mass production and automation production.

- Because the powder is manufactured directly, the raw material cost is cheap, import substitution effect is 100%, and there are no raw material dependencies.

- The cost of parts manufacturing facility is very low compared to that of the conventional titanium melting casting method.

- The price of our titanium parts is comparable to that of stainless steel machined parts.

- Rate of return is more than 30%. The more complex the 3-dimensional shaped parts are, the higher the rate of return is.

Intellectual property right

- It is pure domestic technology.

- Until now, it is the only company in the world that mass-produces titanium parts by using a powder injection method.

- 16 patents have been registered in Korea 1 patent in China. Currently, the company is applying for a patent in USA and Japan.

IPO plan for 2021

Signed stock management contract with Kookmin Bank, account management contract with IBK Investment Securities, expected to conduct appointed audit in 2020.

Signed stock management contract with Kookmin Bank, account management contract with IBK Investment Securities, expected to conduct appointed audit in 2020.

Technology Certification

01Net technology (NET) certified by the Ministry of Knowledge and Economy

02Reliability has been improved by being certified in the "biological safety test (including animal transplantation test)", KFDA standard.

03“ROHS” certification

04Titanium collar:

US dry cleaning test accreditation05Global companies recognize

(Boeing, HP, Oakley, Zimans, Samsung, LG, etc.)06As a result of the confirmation by Ernst & Young, an American Accounting Corporation, currently MTIG's technology is the first one.

MTIG Titanium Parts Sales

- Supplied all dental implant parts to Dental Implant Dio, Denium, Cowell Mede and Warrentech

- Continues to deliver products after delivering titanium anodizing jig worthy of about 2.5 million dollars to Samsung Electronics Vietnam Corporation.

Galaxy S-8, S-8 +, S-8 notes, S-9 +, S-9 notes are being produced using MTIG's jig.

There is no dropped product during the production process, and productivity is drastically improved.

Awarded $ 1 Million Export Tower in 2017. - We are making the best efforts to manufacture titanium parts and to develop new products such as one-body implants.

- The goal is to be listed on KOSDAQ between 2020 and 2021.

| Item | Titanium parts produced by MTIG | Existing (bulk) titanium parts |

|---|---|---|

| Quality of the material | 99.5% or more pure titanium | Same |

| Density of the material | 99.5% or more (the same as bulk theoretically) | 100% |

| Method to manufacture parts | Powder injection molding | Machining |

| Raw materials | Produced and manufactured by the company (import-substituting effect) |

100% imported |

| Productivity | About 30,000 ea/10 hours (manufacturing implant for dentists) |

About 300 ea/10 hours (manufacturing implant for dentists) |

| Production facility (equipment) | Succeeded perfect localization | Imported equipment |

| Cost for production facility | Low | High |

| Production manpower | Manpower for simple table work | Highly skilled manpower |

| Production method | Automation, continuous production 24/365 | Production only during work hours |

| Manufacturing cost | Domestic raw materials + manpower for simple work | Imported raw materials + highly skilled manpower |

| Raw material dependencies | No | 100% |

| Product (parts) price | Less than half (compared with machined titanium parts) |

About 10 times of machined stainless parts |

| Parts market | Low-end market (realized popularization of titanium) |

High-end market |

| Market scalability (segmentation) | Market scalability is high (market for machined stainless parts) |

Market scalability is low (closed market) |

| New parts market opened with the unique features of titanium | Titanium hammer, titanium parts for musical instrument, low-cost medical parts made of titanium (improving human's health and welfare), aerospace plane, national defense and etc. | Sticks to existing high-end market |

| Competition with other company | MTIG is the only company that owns a production factory for manufacturing powder injection molded parts and produces goods. | There are many competitors. |

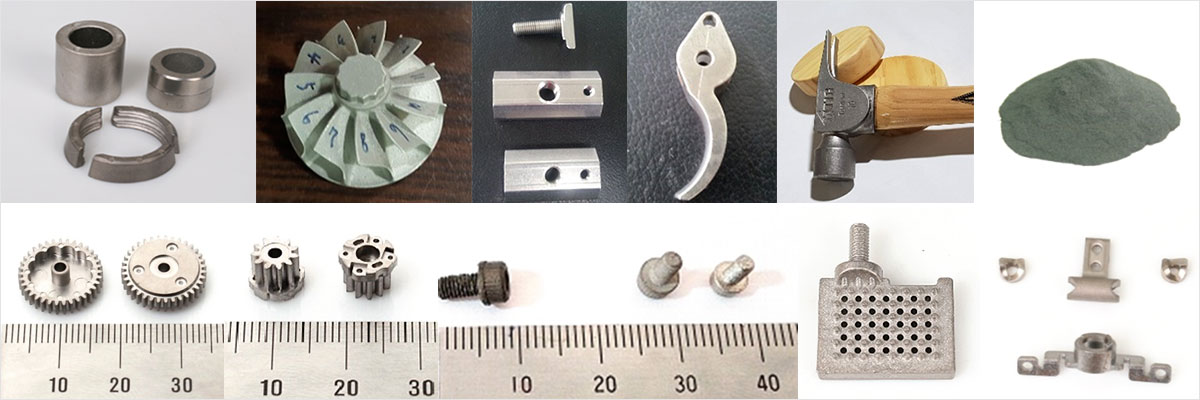

Pictures of major titanium products manufactured by MTIG

-

- 01. Medical Parts

- Manufactures medical parts such as one-body dental implants, bushing parts for implant packaging, and orthopedic implants, etc.

-

- 02. Titanium machine parts

- Robot parts, hinges, washers, high-speed rail parts, turbochargers, gun parts, hammer, titanium powder, etc.

-

- 03. Titanium IT Parts

- Home button, Deco, Earphone cover, Mobile phone case, Smart watch case, Anodizing jig, etc.

-

- 04. Various household goods

- Accessories, buttons, zipper pullers, crosses, fashion accessories, cosmetic applicators, functional sleeping masks, etc.

In addition, we continue to develop many titanium parts such as medical titanium parts, anodizing jigs, and mechanical parts to positively respond to customer needs.